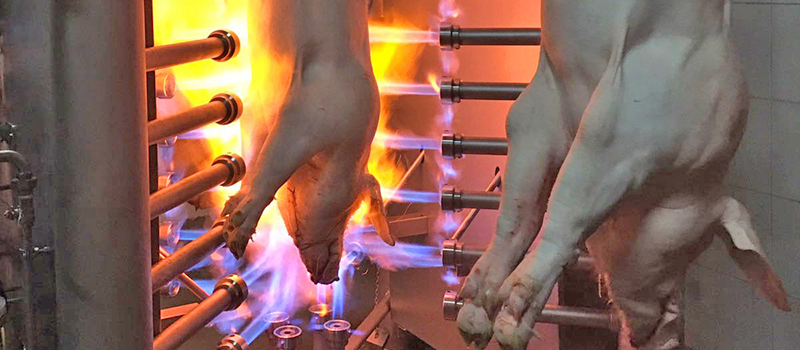

Machinery for Pig Slaughterhouse

The automation of pig slaughter lines is carried out based on production, and it is the part of the line that requires the most labor.

The design and installation of an efficient and productive slaughter line must meet a series of objectives

|

Mecanova has a wide range of products to meet these needs

LINES ADAPTED TO YOUR NEEDS

The experience of more than 35 years guarantees the profitability and quality of Mecanova's pork lines. The continuous growth of pork consumption worldwide requires the construction and modernization of pig slaughter lines. The pig slaughter process is the most complex within the slaughter lines, and therefore the one that requires the most technological investment.

THE CHALLENGE

- 1. Lines with productions adjusted to the needs, with the minimum cost of human effort, thanks to adequate automation

- 2. Low energy consumption lines and minimal water consumption

- 3. Lines that achieve high quality meat and low losses

- 4. Lines that guarantee the safety of the process and eliminate the risk of salmonella or legionella

WHAT DO WE OFFER?

|

LEARN ABOUT OUR PRODUCTION PROCESSES

|  | |

|  | |

|