Pig Dressing

functionality

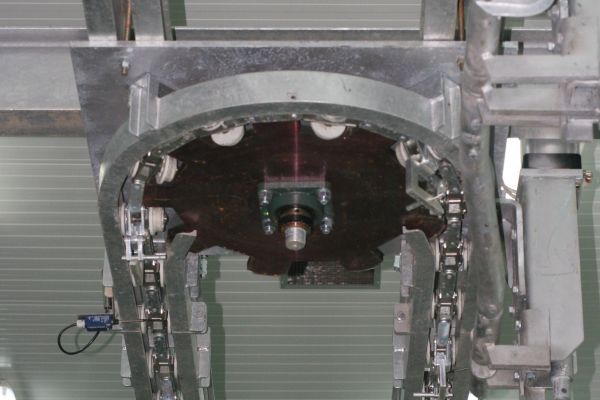

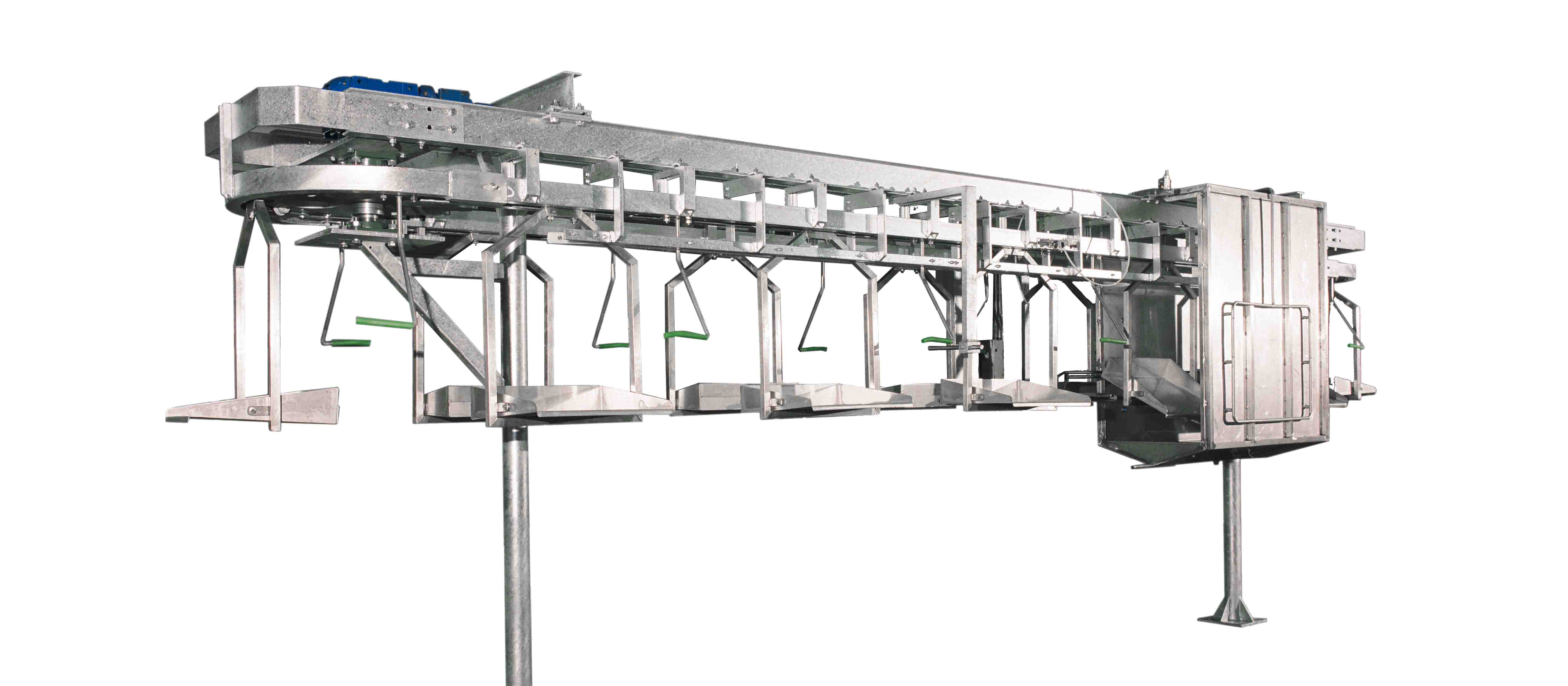

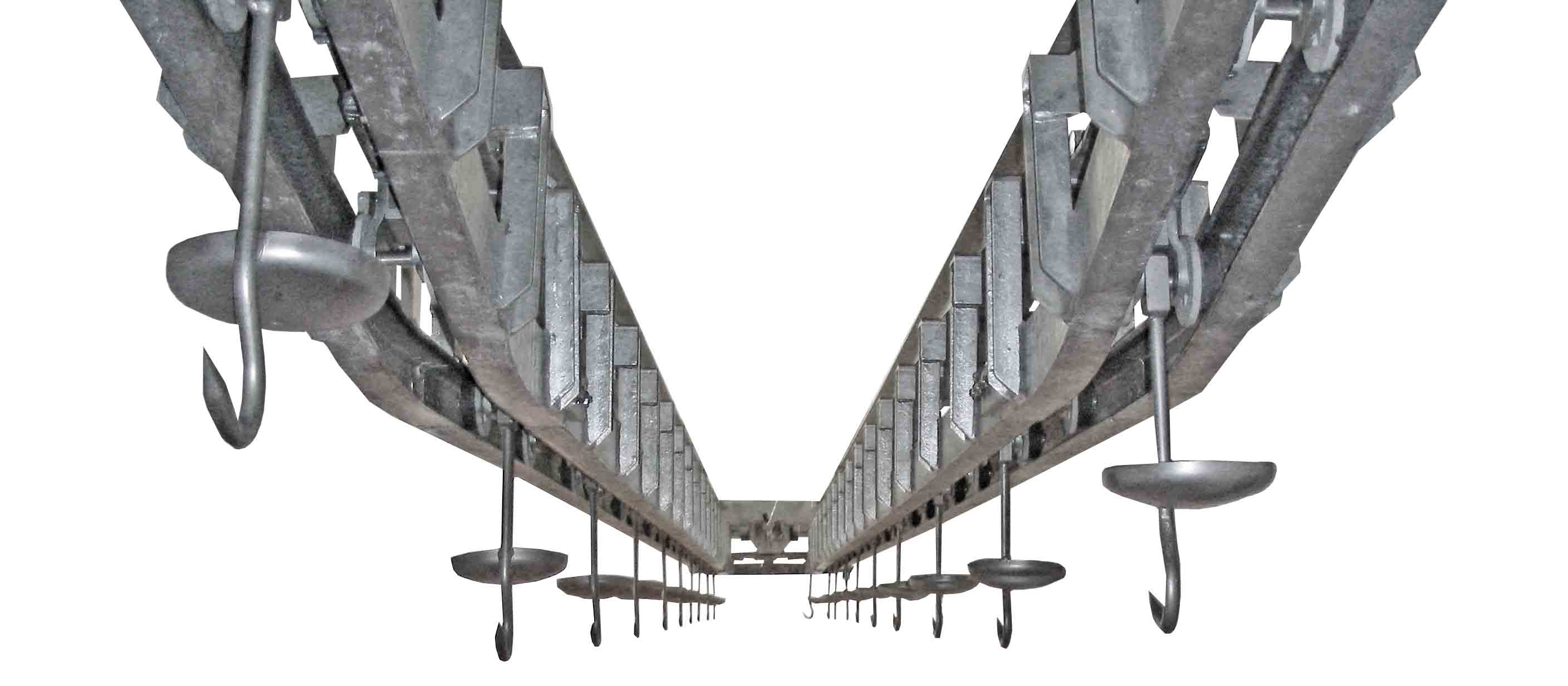

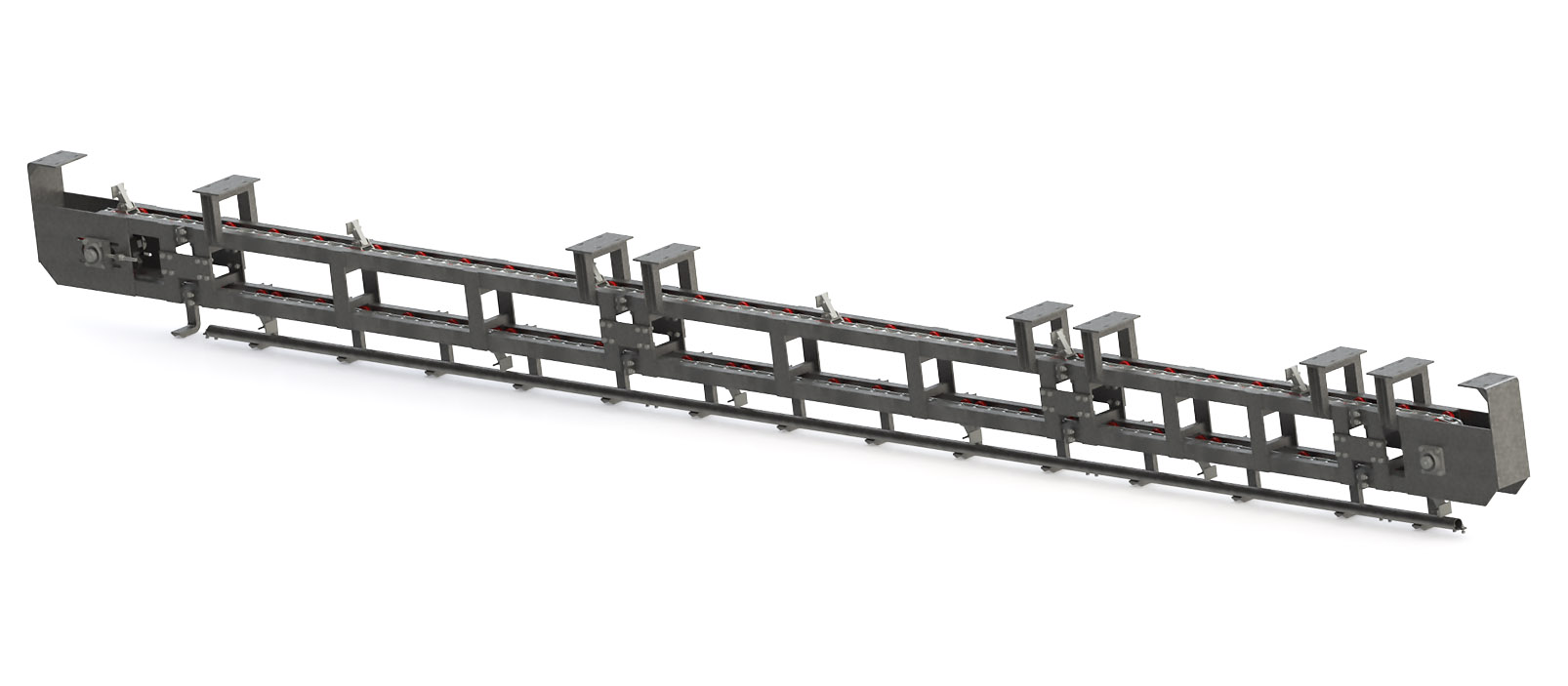

The pig red offal conveyor is a mechanized and automated device with which pork red viscera are moved from the point of extraction to the work room. The route and design of the conveyor is conditioned by the production and the slaughter process. The pig red offal nveyor is recommended for productions greater than 120 animals per hour.

Technical Features

- - Made of S275-JR steel Hot-dip galvanized and screw-mounted

- - The hooks are made of round rod Φ10 in stainless steel

- - Traction by variable power planetary gearmotor

- - The tension is always by pinion with pneumatic balloon tension

- - Automation of the pig red offal conveyor: individual or entire installation electrical panel with frequency inverter and management PLC

Functionality

Pig offal conveyors are designed for the collection and transport of viscera from work platforms to veterinary inspection points. For a correct and coordinated execution of this process, it is needed an adequate and automated equipment.

The extraction of the offal is performed at a point on the dressing line and the veterinary inspection, and it must be carried out in such a way each viscera is identifiable at the inspection point and each viscera can be assigned to its carcass. For this reason, pork viscera conveyors must be designed allowing the perfect synchronization of the viscera conveyor with the dressing line.

Mecanova has different pig offal conveyors depending on each type:

RED OFFAL CONVEYOR |  |

WHITE OFFAL CONVEYOR

|  |

INTEGRAL RED AND WHITE OFFAL CONVEYOR

|  |

Functionality

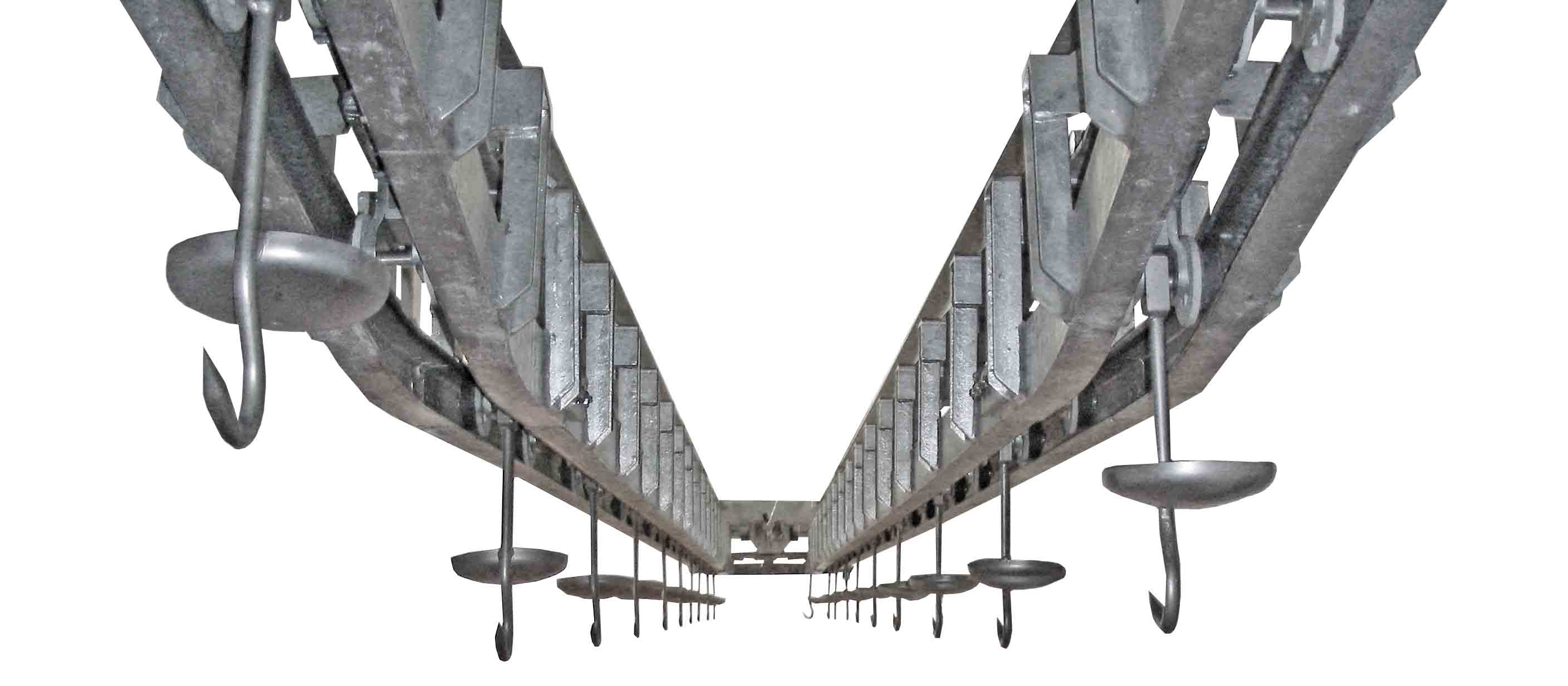

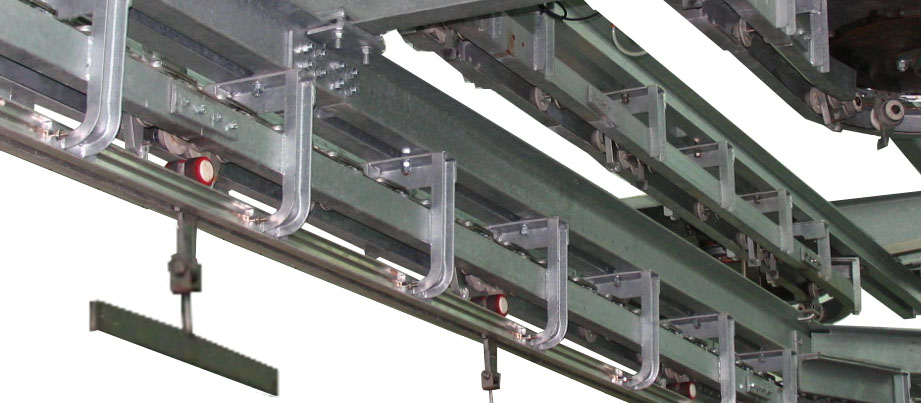

The pig horizontal dressing conveyor is an equipment designed for the pig dressing in production lines of more than 100 pigs per hour. This equipment allows a linear layout or with curves, as its configuration through crowns wheels or horizontal supports allow the transfer of channels in different directions.

This conveyor allows easy protection in the part of the singer burner and guides for fixing the gambrels for a better dressing operation, especially in the evisceration and during the cutting.

advantages of the equipment

- 1. Equipo robusto y resistente

- 2. Cadenas con una alta durabilidad gracias al empleo de cadenas forjadas de los mejores fabricantes europeos

- 3. Sobre este transportador de faenado puede montarse cualquier tipo de vía: tubular, birraíl o pletina

Technical features

- - Robust configuration: the chain circulates at the top, supported by double-wheeled trolleys in a double 80 mm UPN

- - The entire structure of the conveyor is joined by 10 mm laser cut plate supports every 600 mm

- - Assembly bolted to the bearing structure without the need for welding

- - Hot-dip galvanized, although by customer request, a fanning conveyor can be manufactured entirely in stainless steel

- - Planetary geared motor with variable power depending on the load

- - Chain tensioning carried out by means of a tensioner assembly with Z10 sprockets and pneumatic spring Φ 270 L150

- - Automation of slaughter chain conveyors: equipment controlled by an electrical panel with frequency inverter, safety module and programming relay, except in complex installations with several machines, which will be controlled by PLC together with a touch screen for management

Functionality

The pig vertical dressing conveyor is designed for the transport and dressing or slaughter of pig carcasses in an exclusively linear way and is a machinery especially indicated for small dressing productions and for the transport and entry of cooling cameras.

The conveyor is fitted with MC 112 or similar type hollow shaft chains with two sprockets, one for drive and the other for return, both in a vertical position. Any type of meat track can be attached to this vertical dressing conveyor: flat plate, tubular or twin track

Technical Features

- - Structurally made of S275 JR steel

- - The chain has a 100 mm pitch hollow shaft, type MC112 with pushers made of AISI 304 stainless steel.

- - Drive performed by orthogonal geared motor

- - Direct Drive Machinery

- - The equipment is delivered hot-dip galvanized and with modules joined together by screwing.

- - Automation of the slaughter conveyor: the protection and control electrical panel can be the line set or an individual electrical panel

Functionality

The pig dressing conveyor is an equipment whose design is developed based on the characteristics and requirements of each installation. The Mecanova dressing conveyor reaches the required production reliably and without unexpected technical stops, carring satisfactorily all manual or automatic operations.

advantages of the equipment

- 1. Robust and reliable long-lasting equipment

- 2. Machinery with high-quality chains made in Europe

- 3. Hot-dip galvanized structures, maintaining their appearance for many years despite being in high humidity environments

HORIZONTAL DRESSING CONVEYOREquipment for pig dressing linesdesigned for high productions of more than 100 pigs per hour. |  |

VERTICAL DRESSING CONVEYORConveyor for pig dressing lines developed for simpler productions and for the transport of entry to cooling cameras. |  |