Pig Scalding

Once the animal is bled, the carcass cleaning process begins. This requires effective scalding to achieve pore opening and easy removal of hair and epidermis in the subsequent dehairing phase.

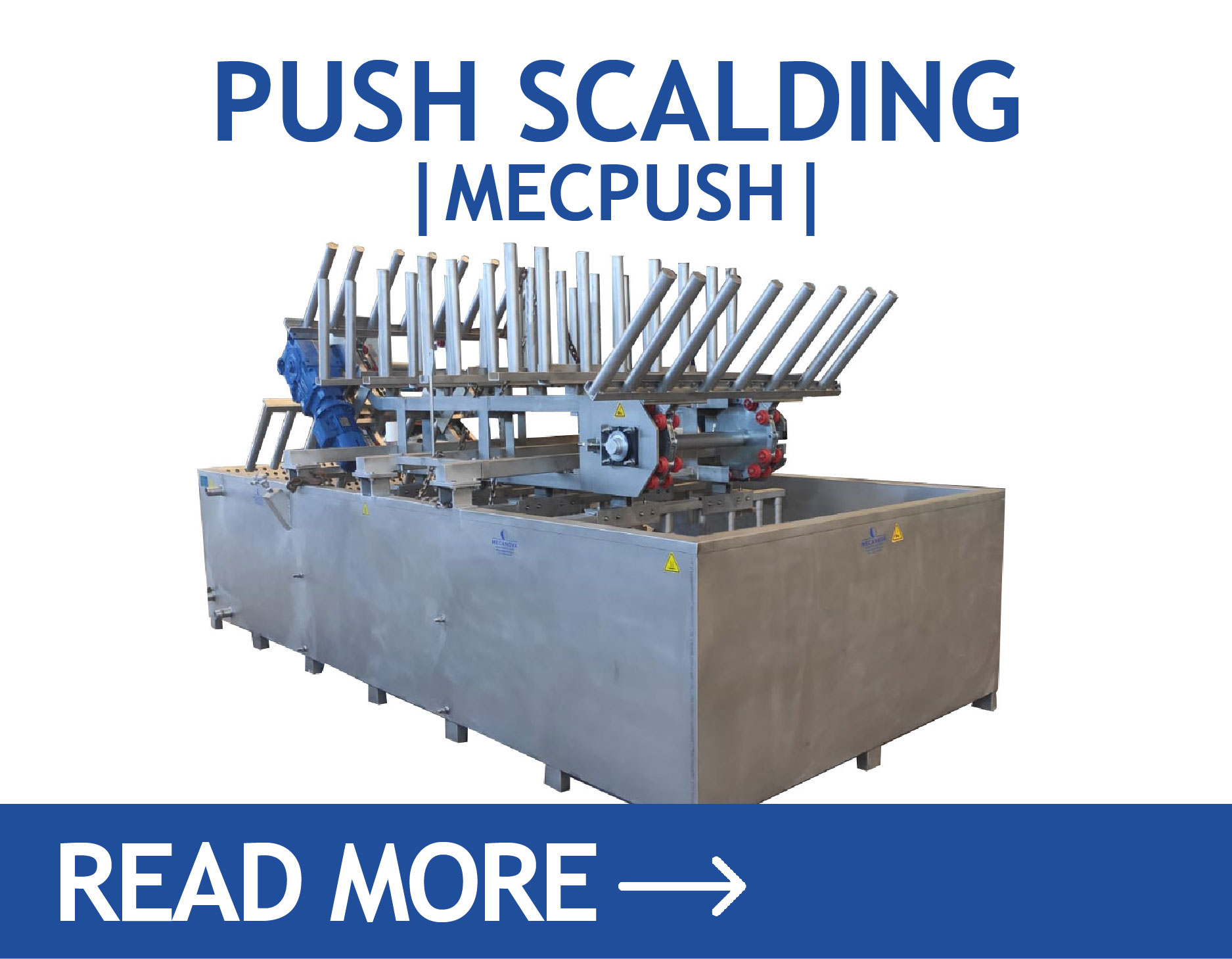

This process is achieved by transmitting temperature to the skin, which is achieved with one of the best heat transmitters available: water. There are different eescaldado systems:

|

- For this reason, Mecanova offers you the system that best suits your needs. We set different goals to meet:

1. To choose the type of scald that best suits your needs and investment conditions 2. Sustainable scalding systems with low energy and water consumption 3. Highest scalding quality |

WHAT DO WE OFFER?

To met these goals, Mecanova offers you, in addition to advice, the most precise equipment

|  |

|  |

|