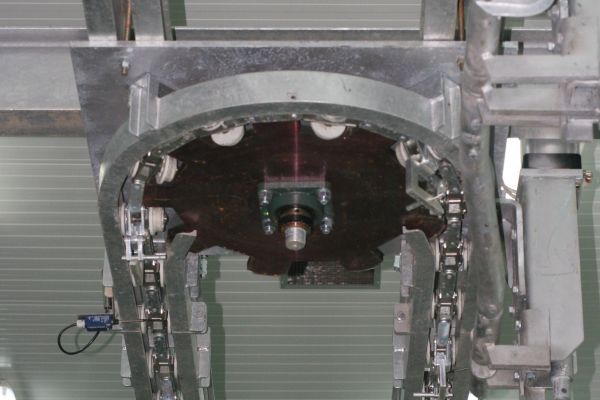

Pig Horizontal Dressing Conveyor

Functionality

The pig horizontal dressing conveyor is an equipment designed for the pig dressing in production lines of more than 100 pigs per hour. This equipment allows a linear layout or with curves, as its configuration through crowns wheels or horizontal supports allow the transfer of channels in different directions.

This conveyor allows easy protection in the part of the singer burner and guides for fixing the gambrels for a better dressing operation, especially in the evisceration and during the cutting.

advantages of the equipment

- 1. Equipo robusto y resistente

- 2. Cadenas con una alta durabilidad gracias al empleo de cadenas forjadas de los mejores fabricantes europeos

- 3. Sobre este transportador de faenado puede montarse cualquier tipo de vía: tubular, birraíl o pletina

Technical features

- - Robust configuration: the chain circulates at the top, supported by double-wheeled trolleys in a double 80 mm UPN

- - The entire structure of the conveyor is joined by 10 mm laser cut plate supports every 600 mm

- - Assembly bolted to the bearing structure without the need for welding

- - Hot-dip galvanized, although by customer request, a fanning conveyor can be manufactured entirely in stainless steel

- - Planetary geared motor with variable power depending on the load

- - Chain tensioning carried out by means of a tensioner assembly with Z10 sprockets and pneumatic spring Φ 270 L150

- - Automation of slaughter chain conveyors: equipment controlled by an electrical panel with frequency inverter, safety module and programming relay, except in complex installations with several machines, which will be controlled by PLC together with a touch screen for management