Pig Scalding

Functionality

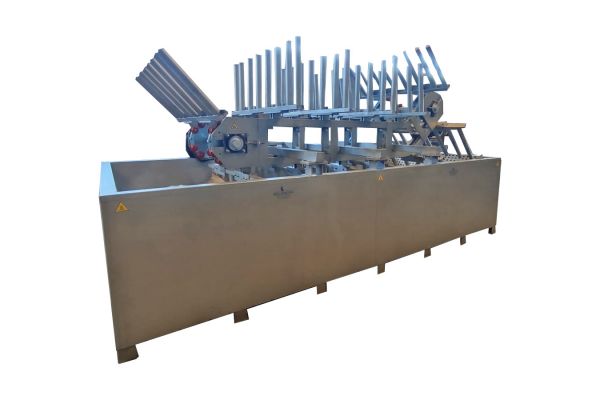

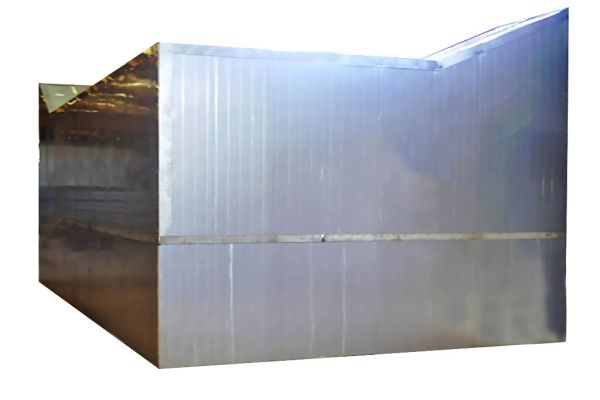

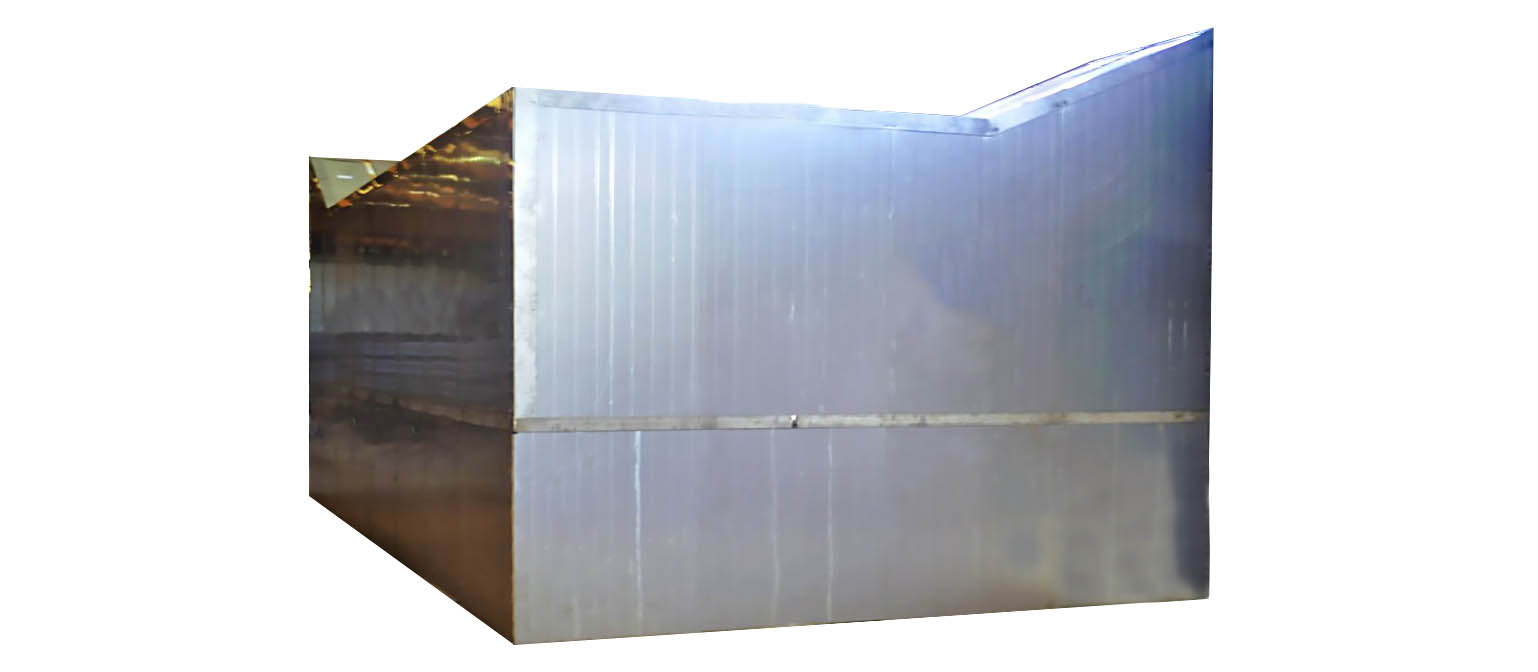

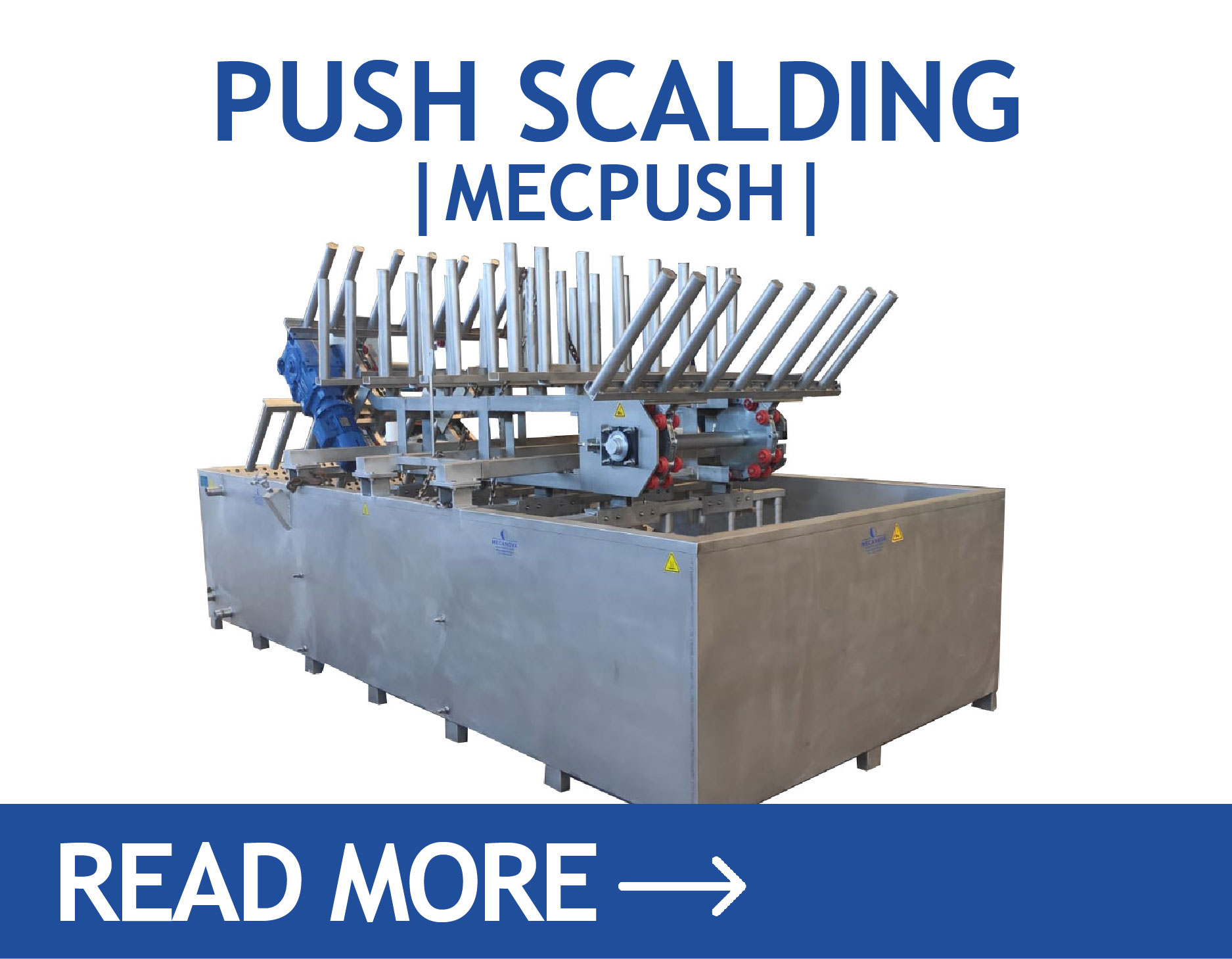

It is a scalding system designed for facilities with productions of between 80 and 150 pigs per hour, depending on the size of the animals, the animal husbandry climatology and the breed. The scalding comprises a traditional raft on which a conveyor is mounted with push combs pulled by a double chain and a 2.2 kW gear motor. The heating system is by direct steam modulated by an ARI brand pneumatic valve.

This equipment allows to control the scalding time of each animal, improving its quality. The temperature control is from high pressure to tenth of a degree centigrade.

advantages of the equipment

- 1. Compact and easy to assemble scalding system

- 2. Robust and resistant equipment, with little maintenance

- 3. Amortization of the investment between 1 and 3 years

Technical Features

- - Made of AISI 304 stainless steel

- - Scalding is controlled by an electrical panel (it is budgeted separately or within the general framework of the slaughterhouse that works depending on the dehairing cycles)

- - The electrical panel enables the planning of water heating

- - The equipment includes water overflow

- - The raft is structurally manufactured with 80x80x3 stainless tube

- - The inner sheets are 3 mm thick and the extensions are 1.5 mm and it includes internal technical insulation using rock wool

- - The push conveyor with its combs is made of stainless steel, although the drive sprockets and chains are made of zinc-plated steel

- - 2'2 Kw Bonfigliori brand motor

Other Products

vertical spray scalding | ROTATING SCALDING | DRAG SCALDING | ||

|  |  | ||

| |

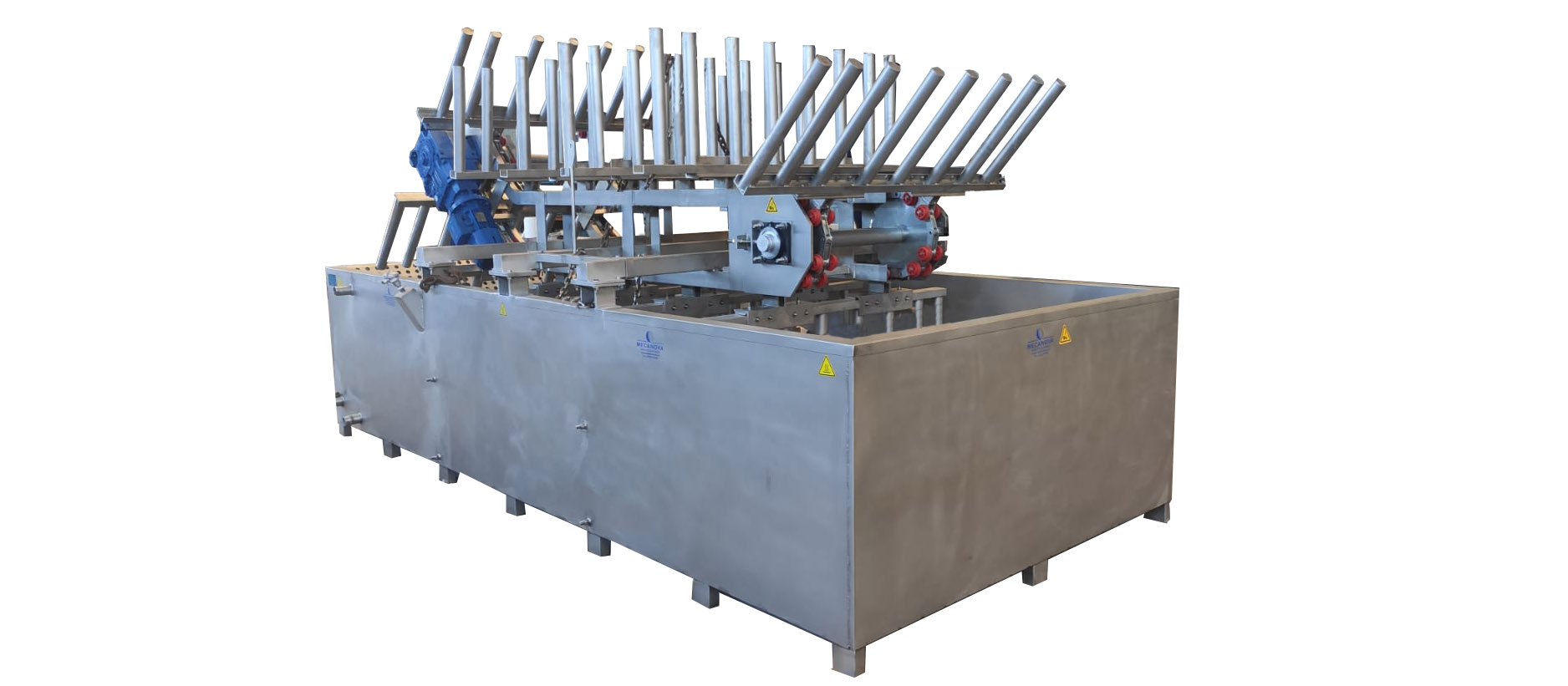

FuncTIONALITY

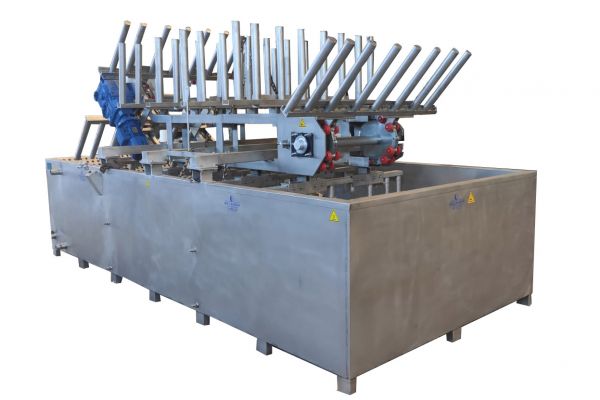

The Mecanova MECPULL scalding system is easy to install in any production line. It is recommended for productions of between 120 and 300 pigs per hour, although it can be designed for higher productions. The MECPULL requires a conveyor, which drags the pigs through the scalding, overcoming the strong gap between bleeding and scalding.

The heating is carried out by steam throughout the entire machine. Temperature control is achieved through a pneumatic steam modulation valve.

ADVANTAGES OF THE EQUIPMENT

- 1. Fast and highly accurate water heating system

- 2. Optimized design for minimal water consumption

- 3. Needs low maintenance

tECHNICAL fEATURES

- - The length and the design will be according to the production and flow within the scalding area.

- - Made of AISI 304 stainless steel

- - Water recirculation steam pipes in stainless steel with diameter depending on design and production. The bypass is made with a cast iron valve

- - Pig unscrambler at the entrance

- - Water heating systems by direct injection of steam controlled by a valve using ARI brand pneumatics or similar. Includes safety bypass, vacuum breaker and non-return valve

- - Recommended carcass spacing 1000 mm

- - Recommended operating temperature: between 60º- 65º

- - Recommended scalding time depending on the weather and breed, between 4 and 6 minutes

Other Products

vertical spray scalding | ROTATING SCALDING | PUSH SCALDING | ||

|  |  | ||

| |

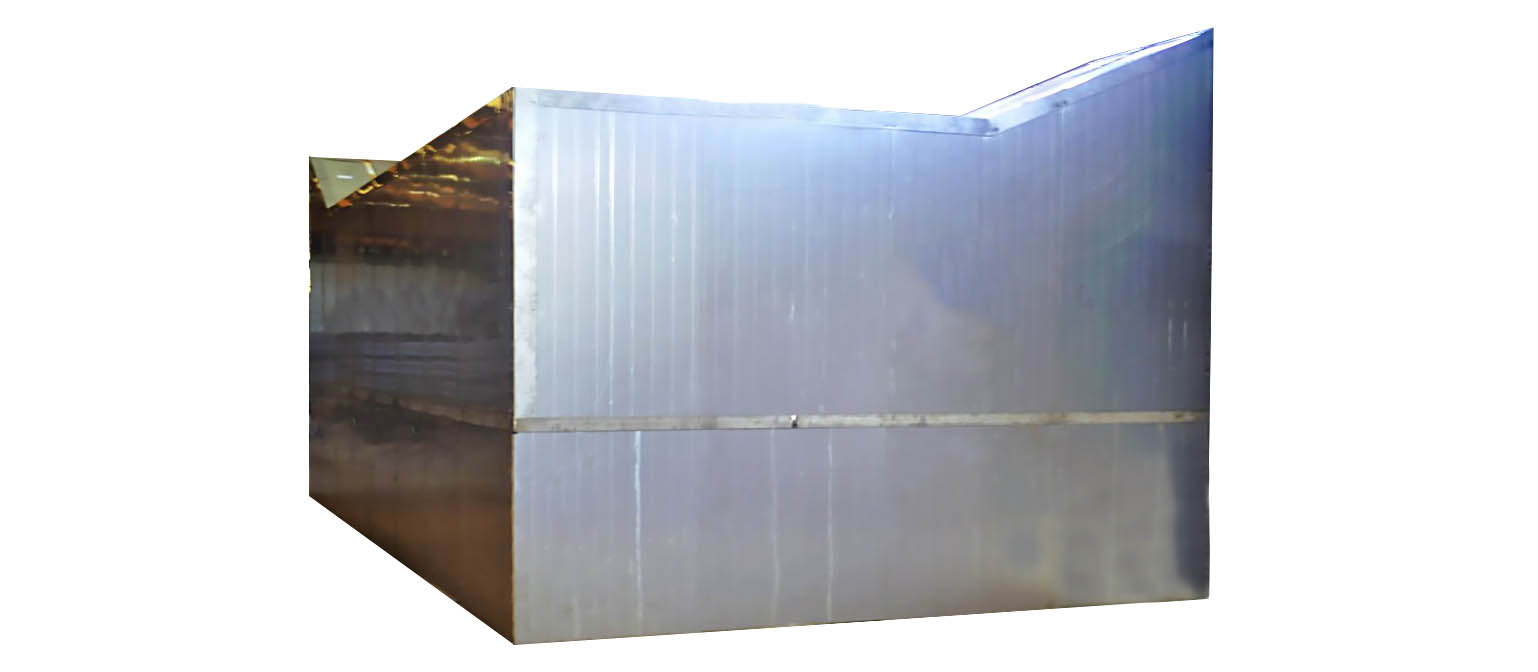

Functionality

The vertical pig scalding system is, the most efficient and sanitary scalding system for productions from 120 pigs per hour.

The machine comprises a tunnel of variable length and layout along which the pig carcasses are showered with water for a time ranging between 4.5 and 6.5 minutes at temperatures between 60 and 64ºC. The carcasses are transported by a track system conveyor continuously and vertically along the tunnel, receiving a continuous shower of hot water.

The equipment has a water basin in the lower part that serves to submerge the animal's head, heat the water to the required temperature, and to aspirate and shower the carcasses with it.

Advantages of the equipment

- 1. Achieves a higher quality of scalding in less time

- 2. The vertical scald by shower consumes 58% less than other scalding systems

- 3. By not submerging the carcass, it eliminates the risk of contamination of it, either through the mouth or through the lungs through the wound.

Technical Features

- - Made of stainless steel AISI 304

- - 5 mm thick stainless steel sheet

- - 80 mm thick stainless steel insulating panels on the top and ceiling and 60 mm on the bottom

- - ARIS brand steam control valves

- - Bomba de agua 3kw Water pump 3kw 100m3 h

- - Water pump 3kw 100m3 h

- - Swing entry and exit doors

- - Electrical panel for protection, control and temperature control with IP65 protection

Learn how it works:

Other Products

PUSH SCALDING | ROTATING SCALDING | DRAG SCALDING | ||

|  |  | ||

| |

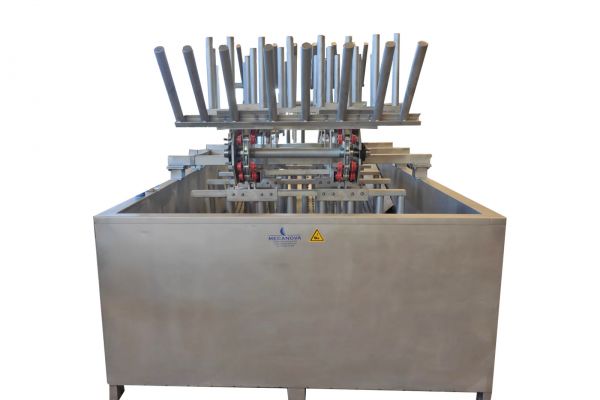

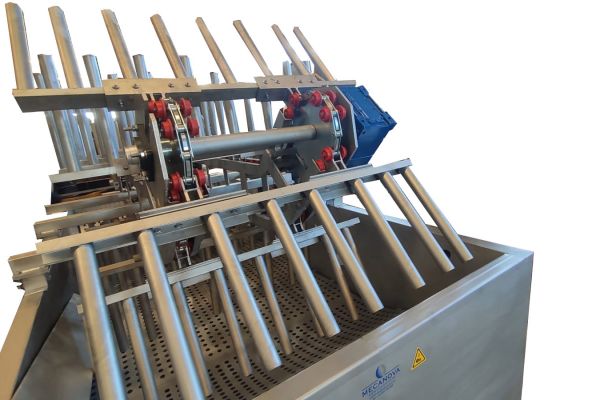

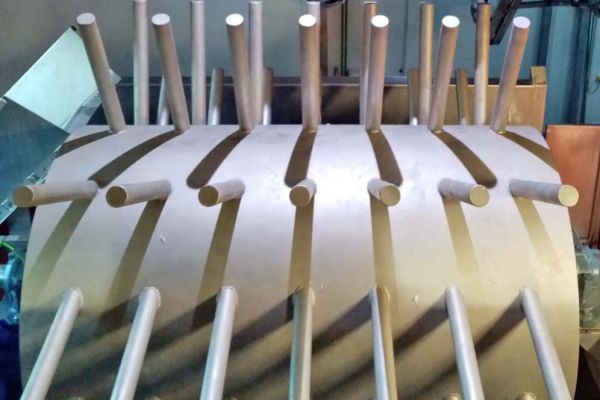

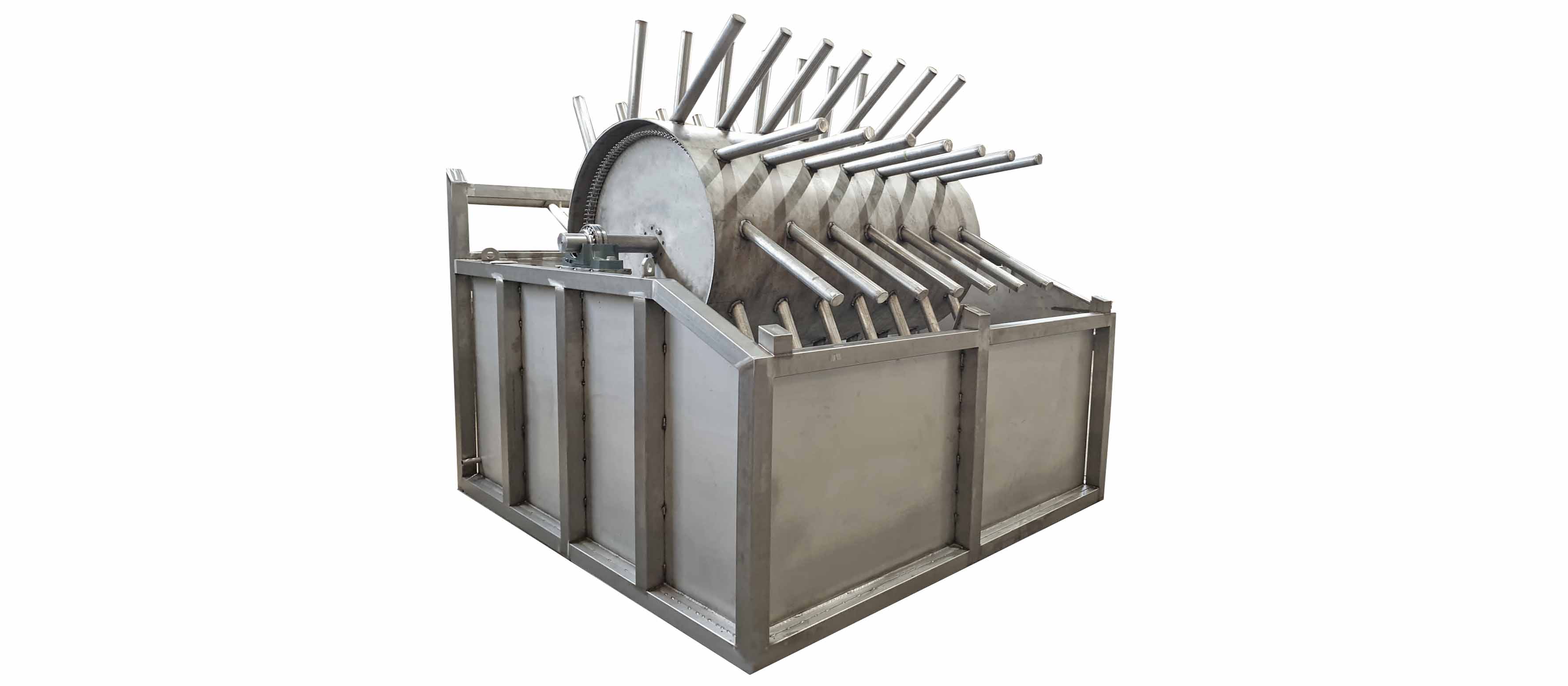

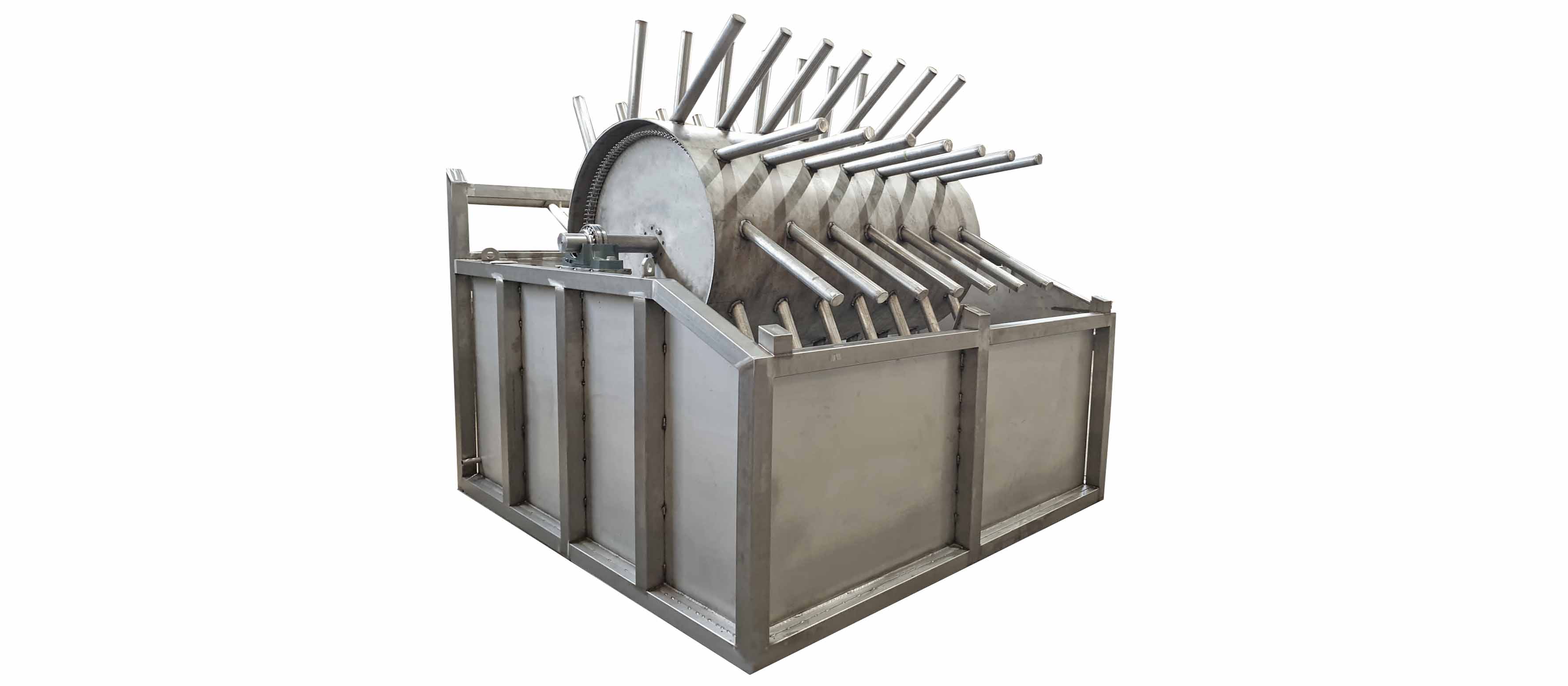

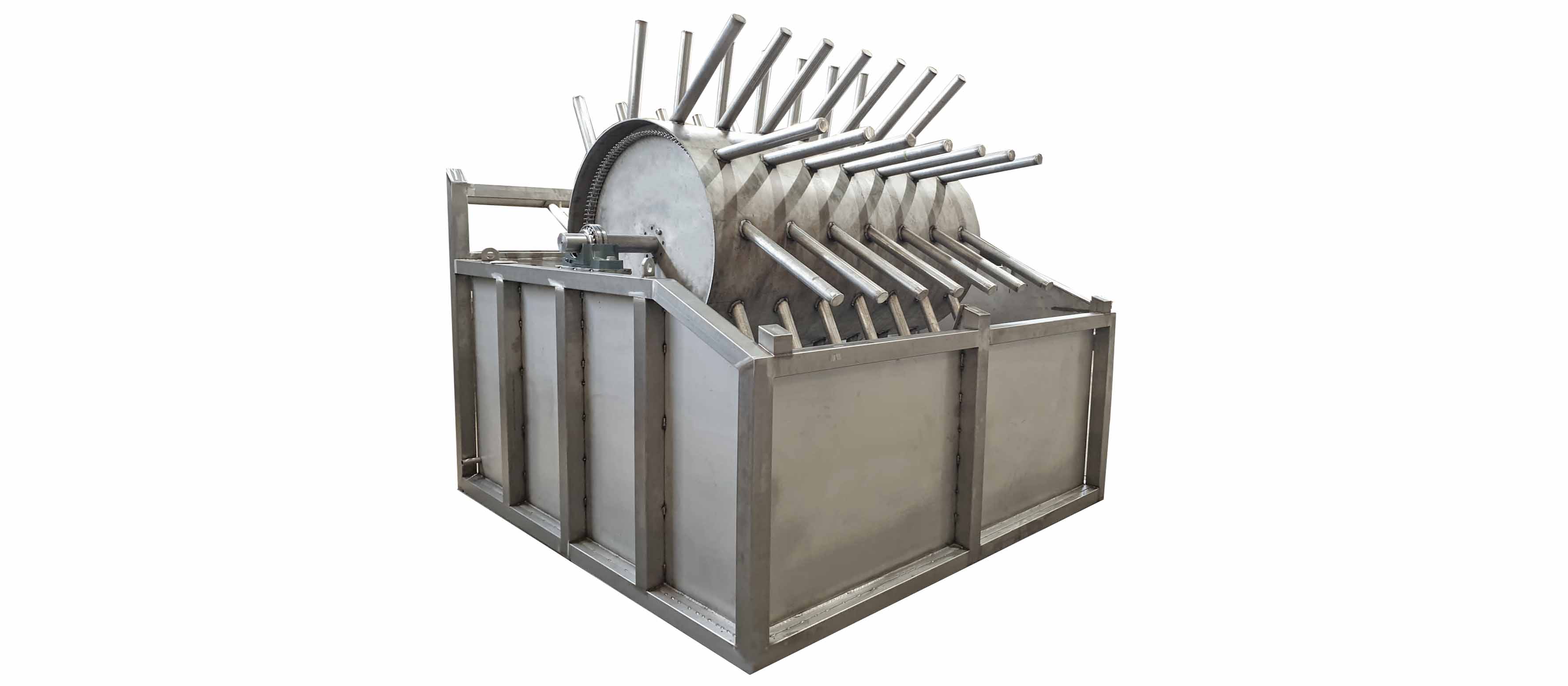

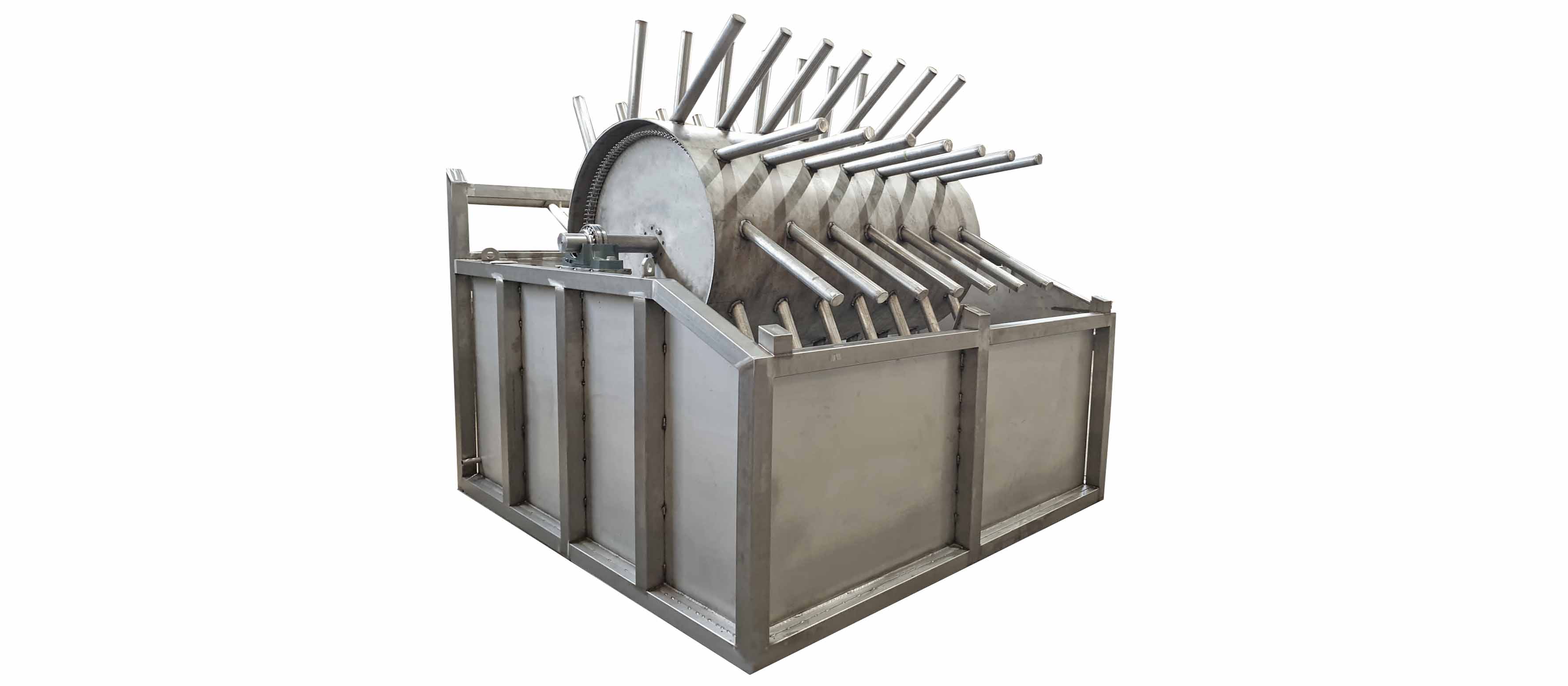

Functionality

The Mecanova MECROT scalding is an ideal machine for automating production lines between 50 and 150 pigs per hour where there is also little space in the facility. Production will depend on the climate of the animal beeding area, and can be used to automate the line and replace traditional rafts, reducing at least one line operator. The return on investment ranges from one to three years.

The machine receives the channels in the upper part, and works in steps, conditioned by the dehairing machine cycles.

The carcasses are submerged in the scald raft, keeping four animals in water if it is the MECROT-1 model and eight, if it is the MECROT-2 model. Heating of the water is carried out by direct steam.

advantages of the equipment

- 1. Compact machine built with high quality materials and

- 2. Low maintenance

- 3. Easy assembly and commissioning

Technical Features

- - Made of AISI 304 stainless steel

- - Rock canvas insulation throughout the raft

- - Drum set made of 8 mm thick stainless steel rolled sheet

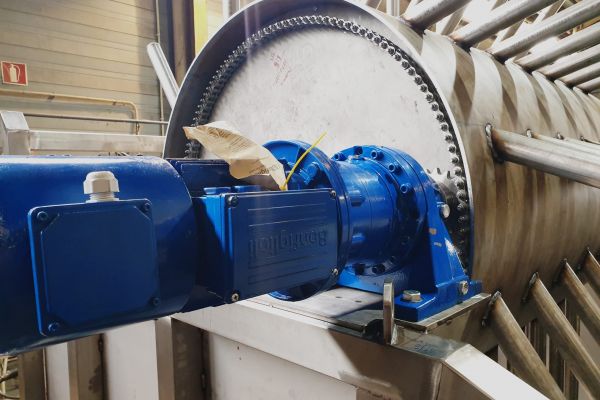

- - Traction by gearmotor with 3 kW brake and C4 corrosion protection

- - Water heating by direct steam modulated by ARI brand pneumatic valve

- - Includes automatic manual fill, drain and overflow valve

- - The scalding control allows planning the start time of the water heating

Learn how it works:

Other Products

vertical spray scalding | PUSH SCALDING | DRAG SCALDING | ||

|  |  | ||

| |

Once the animal is bled, the carcass cleaning process begins. This requires effective scalding to achieve pore opening and easy removal of hair and epidermis in the subsequent dehairing phase.

This process is achieved by transmitting temperature to the skin, which is achieved with one of the best heat transmitters available: water. There are different eescaldado systems:

|

- For this reason, Mecanova offers you the system that best suits your needs. We set different goals to meet:

1. To choose the type of scald that best suits your needs and investment conditions 2. Sustainable scalding systems with low energy and water consumption 3. Highest scalding quality |

WHAT DO WE OFFER?

To met these goals, Mecanova offers you, in addition to advice, the most precise equipment

|  |

|  |

|