Pig Vertical Spray Scalding

Functionality

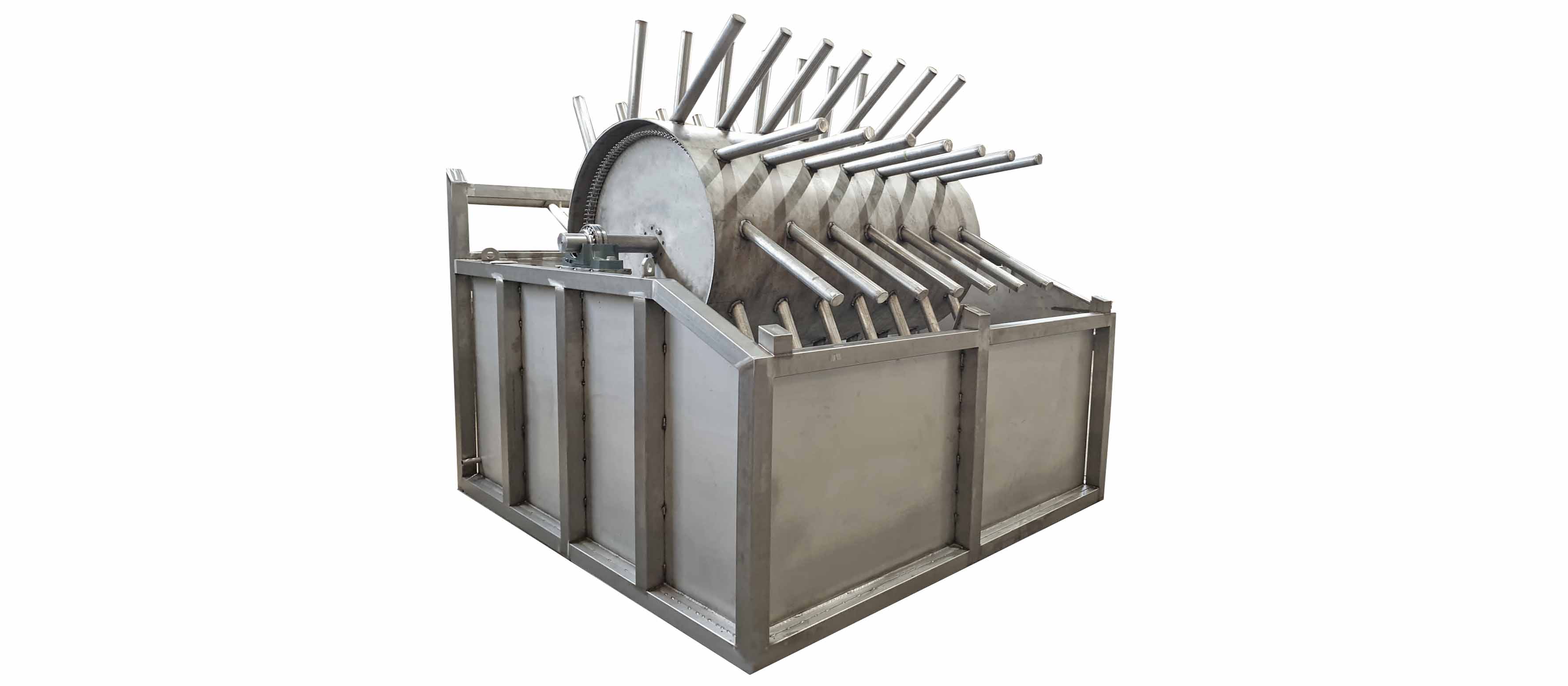

The vertical pig scalding system is, the most efficient and sanitary scalding system for productions from 120 pigs per hour.

The machine comprises a tunnel of variable length and layout along which the pig carcasses are showered with water for a time ranging between 4.5 and 6.5 minutes at temperatures between 60 and 64ºC. The carcasses are transported by a track system conveyor continuously and vertically along the tunnel, receiving a continuous shower of hot water.

The equipment has a water basin in the lower part that serves to submerge the animal's head, heat the water to the required temperature, and to aspirate and shower the carcasses with it.

Advantages of the equipment

- 1. Achieves a higher quality of scalding in less time

- 2. The vertical scald by shower consumes 58% less than other scalding systems

- 3. By not submerging the carcass, it eliminates the risk of contamination of it, either through the mouth or through the lungs through the wound.

Technical Features

- - Made of stainless steel AISI 304

- - 5 mm thick stainless steel sheet

- - 80 mm thick stainless steel insulating panels on the top and ceiling and 60 mm on the bottom

- - ARIS brand steam control valves

- - Bomba de agua 3kw Water pump 3kw 100m3 h

- - Water pump 3kw 100m3 h

- - Swing entry and exit doors

- - Electrical panel for protection, control and temperature control with IP65 protection

Learn how it works:

Other Products

PUSH SCALDING | ROTATING SCALDING | DRAG SCALDING | ||

|  |  | ||

| |