Pig Dynamic Hanging Table

Functionality

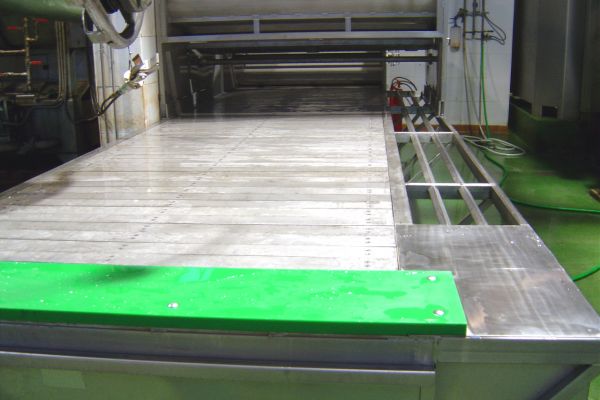

The pig dynamic hanging table is placed at the exit of the continuous dehairing machines for pigs, being the support on which the carcass is received and prepared for hanging on the gambrels.

The production of more than 200 pigs per hour requires a significant speed in the hanging of the animals, and therefore it is necessary to facilitate the operation to achieve maximum productivity and reduce operator fatigue.

That is why the dynamic pig hanging tables greatly facilitate the ergonomics and productivity of this operation, as the carcass is placed perpendicular to the elevator. The carcasses move closer to the point of introduction to the elevator, and while the operators have enough time to carry out other tasks such as hoof removal or pricking. Other complementary and optional elements are the pig carcass positioning systems or the horizontal pig carcass elevators.

The dynamic hanging table is recommended from a production of more than 180 pigs per hour. There are two types depending on their production. For high productions, the dynamic table with stainless steel band is a resistant and efficient machine, and for slightly smaller productions, the dynamic table with polyethylene band perfectly fulfills the function for a more economical price.

Technical Features

Dynamic Table with polyethylene band

- - Structurally made of AISI 304 stainless steel

- - Traction by means of a geared motor with a 60x60 solid stainless steel shaft of 1.5 Kw

- - Modular polyethylene conveyor belt

- - Standard dimensions length, width and height: 4500x2200x855

dynamic table with stainless steel

- - Structurally made of AISI 304 stainless steel

- - Traction by stainless steel Φ 60 shaft with 2.2 KW geared motor with Z10 pinions in F114 zinc plated

- - Stainless steel MC56 type chain with fins on which 100x8mm stainless steel slats are mounted, forming a conveyor belt