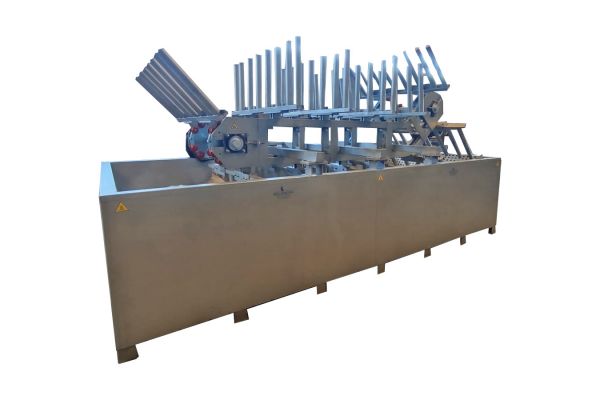

Pig Push Scalding

Functionality

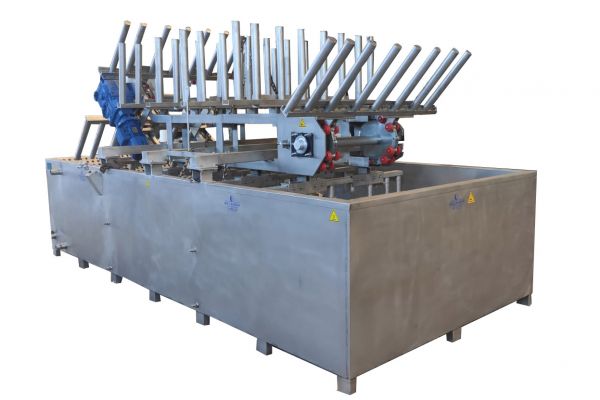

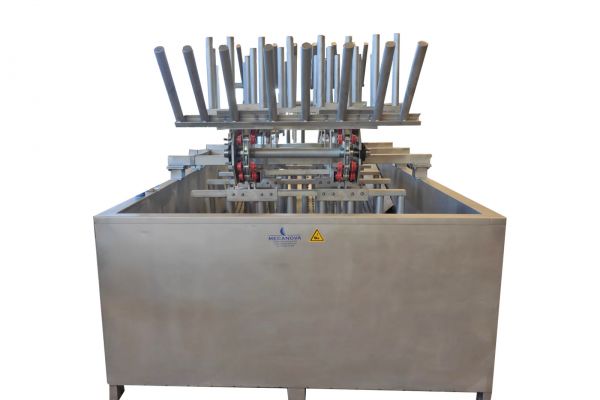

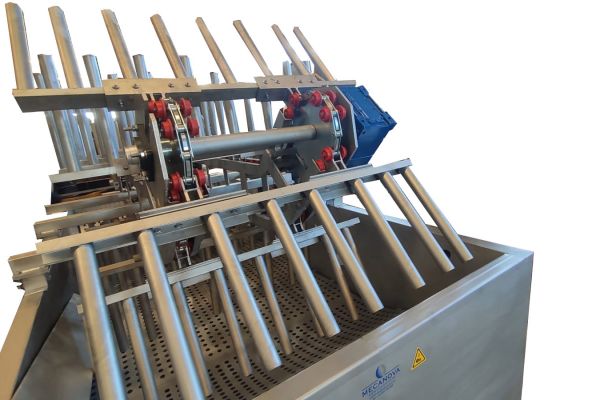

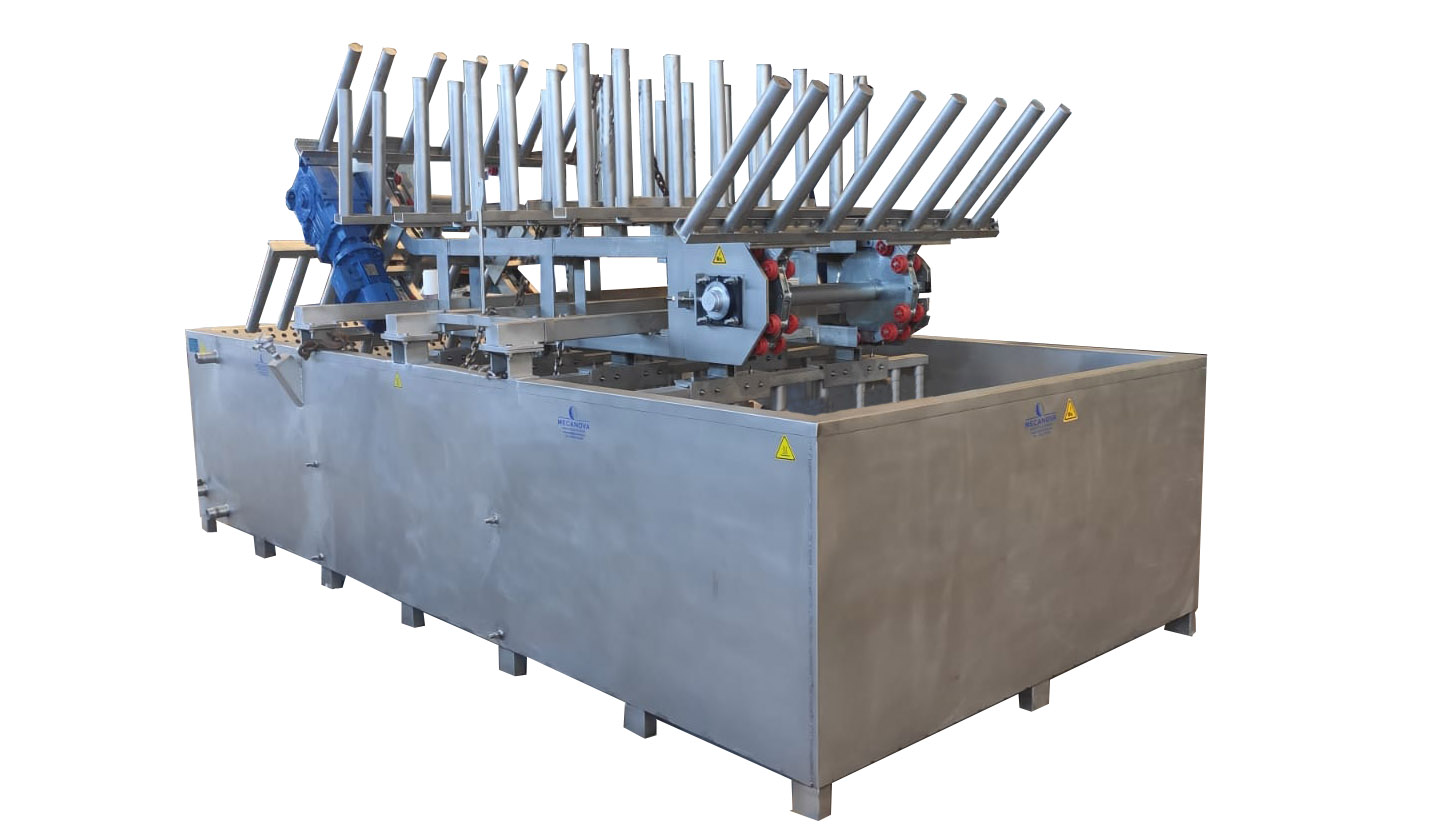

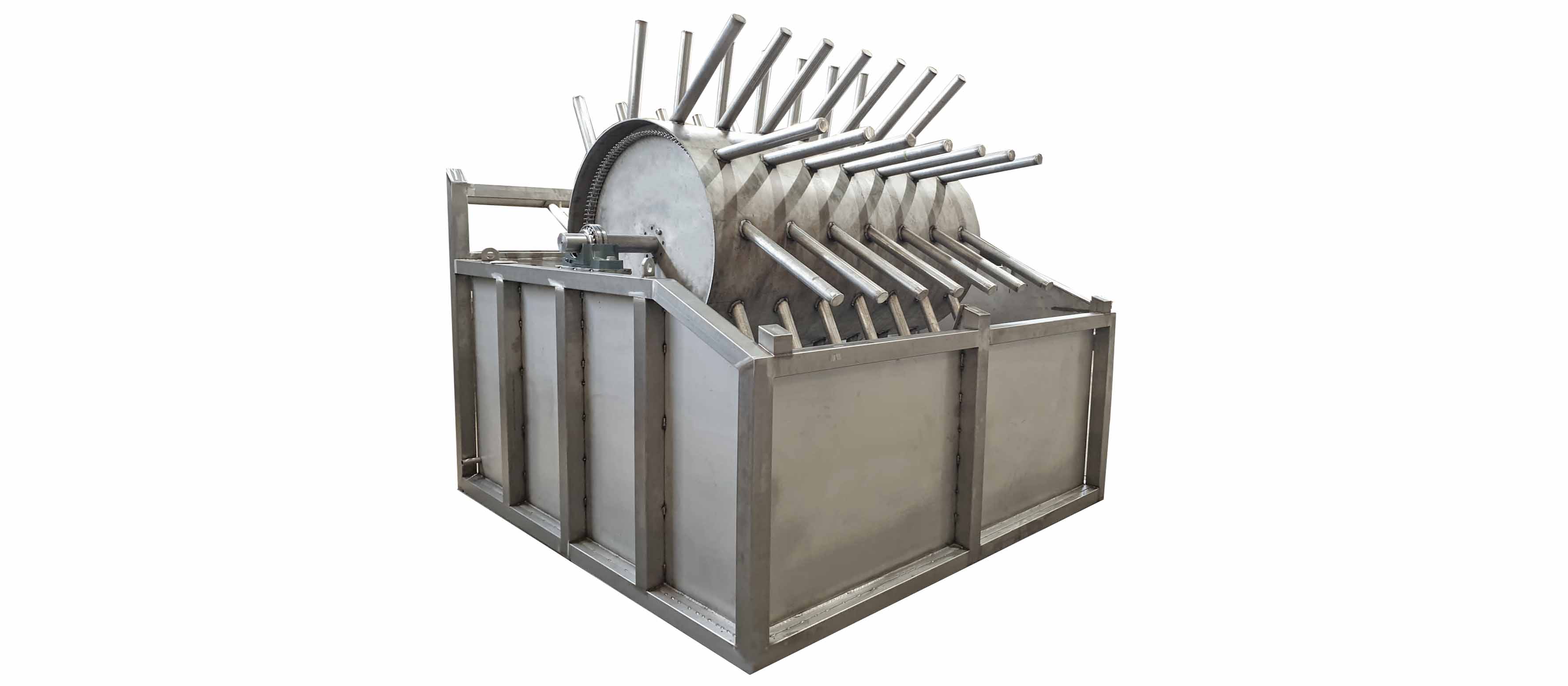

It is a scalding system designed for facilities with productions of between 80 and 150 pigs per hour, depending on the size of the animals, the animal husbandry climatology and the breed. The scalding comprises a traditional raft on which a conveyor is mounted with push combs pulled by a double chain and a 2.2 kW gear motor. The heating system is by direct steam modulated by an ARI brand pneumatic valve.

This equipment allows to control the scalding time of each animal, improving its quality. The temperature control is from high pressure to tenth of a degree centigrade.

advantages of the equipment

- 1. Compact and easy to assemble scalding system

- 2. Robust and resistant equipment, with little maintenance

- 3. Amortization of the investment between 1 and 3 years

Technical Features

- - Made of AISI 304 stainless steel

- - Scalding is controlled by an electrical panel (it is budgeted separately or within the general framework of the slaughterhouse that works depending on the dehairing cycles)

- - The electrical panel enables the planning of water heating

- - The equipment includes water overflow

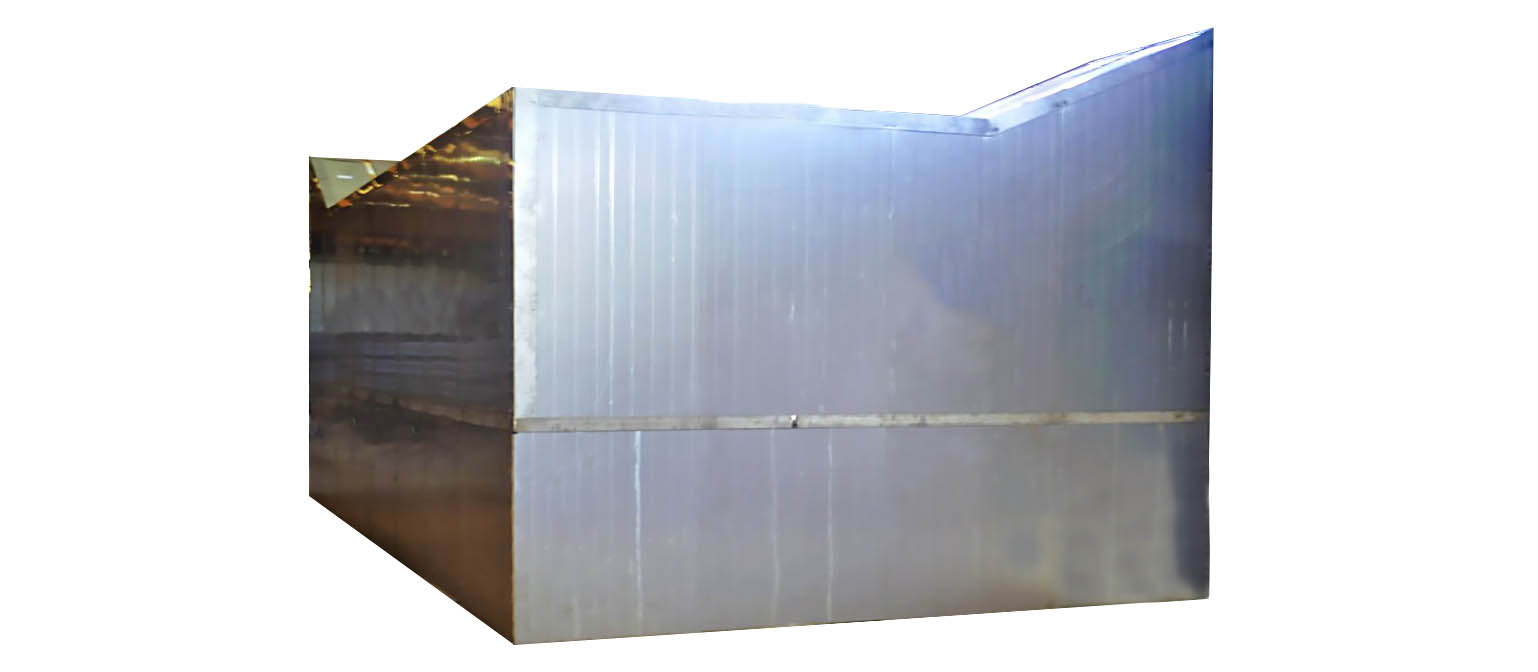

- - The raft is structurally manufactured with 80x80x3 stainless tube

- - The inner sheets are 3 mm thick and the extensions are 1.5 mm and it includes internal technical insulation using rock wool

- - The push conveyor with its combs is made of stainless steel, although the drive sprockets and chains are made of zinc-plated steel

- - 2'2 Kw Bonfigliori brand motor

Other Products

vertical spray scalding | ROTATING SCALDING | DRAG SCALDING | ||

|  |  | ||

| |