Aluminium Twin Track System

Functionality

The aluminium twin track system is the most modern, economical, safe and clean rail model on the market. The different elements of this structure make it a leading model and up to scratch, meeting the expectations and needs of the producer.

It is composed by several elements such as the track made of extruded aluminium, hangers or switches of two and three directions.

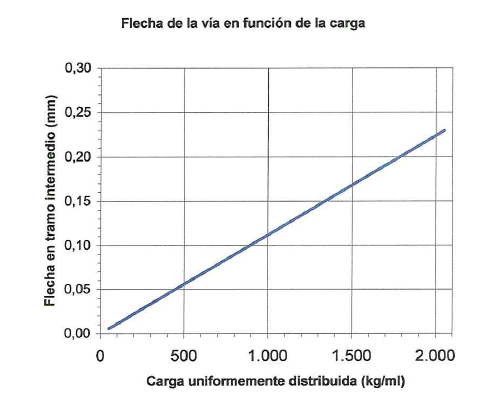

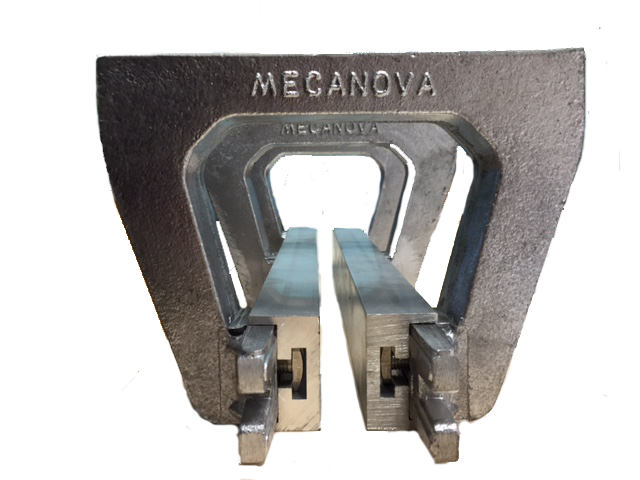

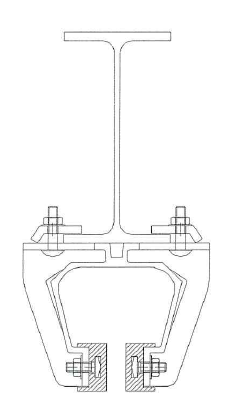

| Mecanova's aluminium profile has a design that provides it with a high loading capacity, a long service life and a easy screw to the hanger. The gravity cast aluminium hangers are highly resistant with a tensile breaking load of 2,240 kg. |  |

| The hanger's desing makes it possible to easily screw the profile to the hanger, and the hanger to the structure. The design is indicated for the take down from a portable structure IPE or IPM (Double T) galvanized in heat. It can also be taken down from an unseen structure above the panel by stainless steel off-hooks. Mecanova places the hangers every 600 mm, although this separation can be adapted to different requirements. |  |

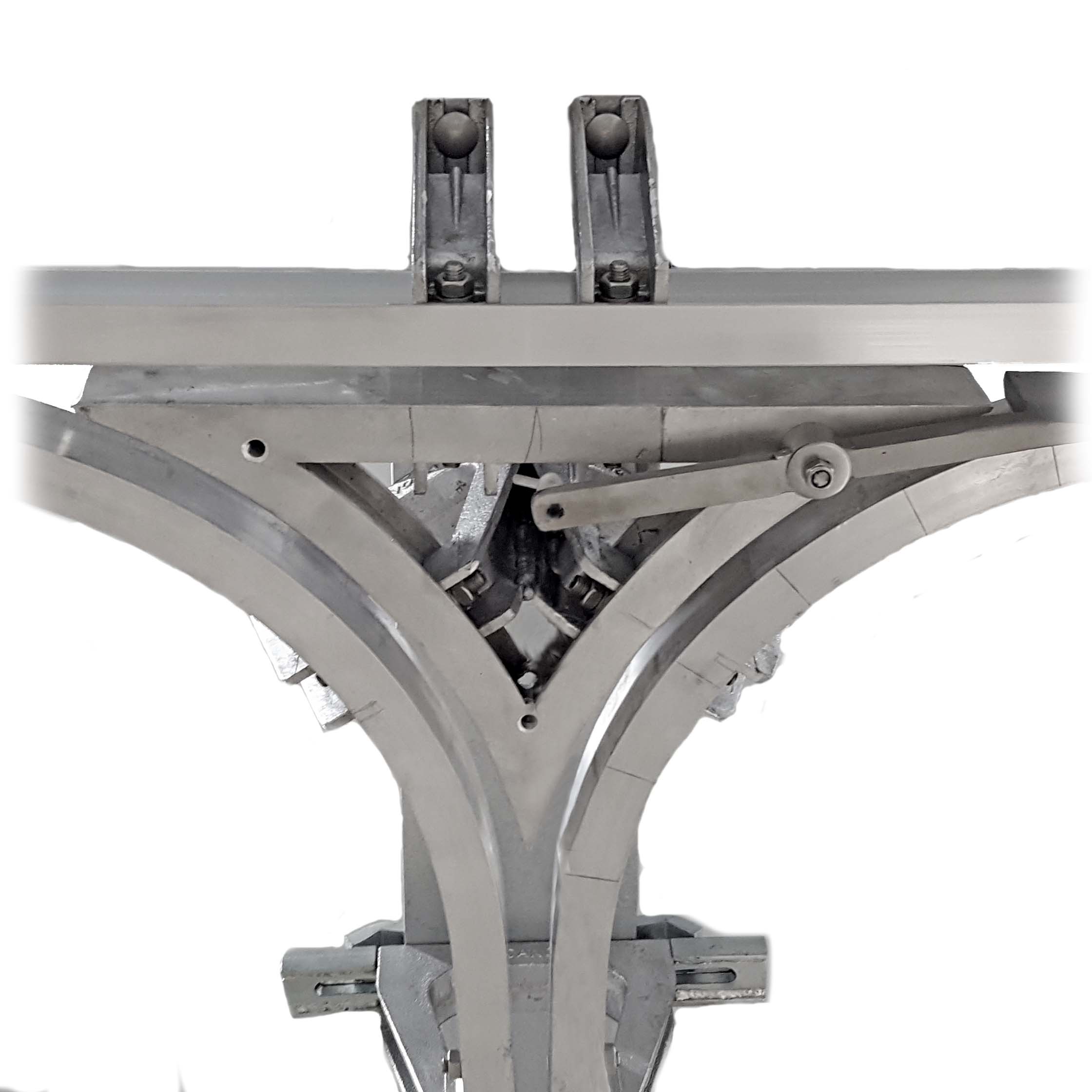

A twin track system switch can be in two or three directions. These usually have built-in drills for the placement of manual needles. Mecanova can also offer detours with pneumatic needles. |  |

equipment Advantages

- 1. The highest quality in the market

- 2. A long experience, translated in a quick execution

- 3. Structure calculation and design included

Technical features

|  |

LEGAL REQUIREMENTS

|

ALUMINIUM TRACK SYSTEM | |

Support Structure in Galvanized Steel |

Other products

inox Twin track system | Trolleys and hooks | Lattice inox Twin Track System | ||

|  | |||