Pallet Turner: Process Automation in Meat Cold Rooms

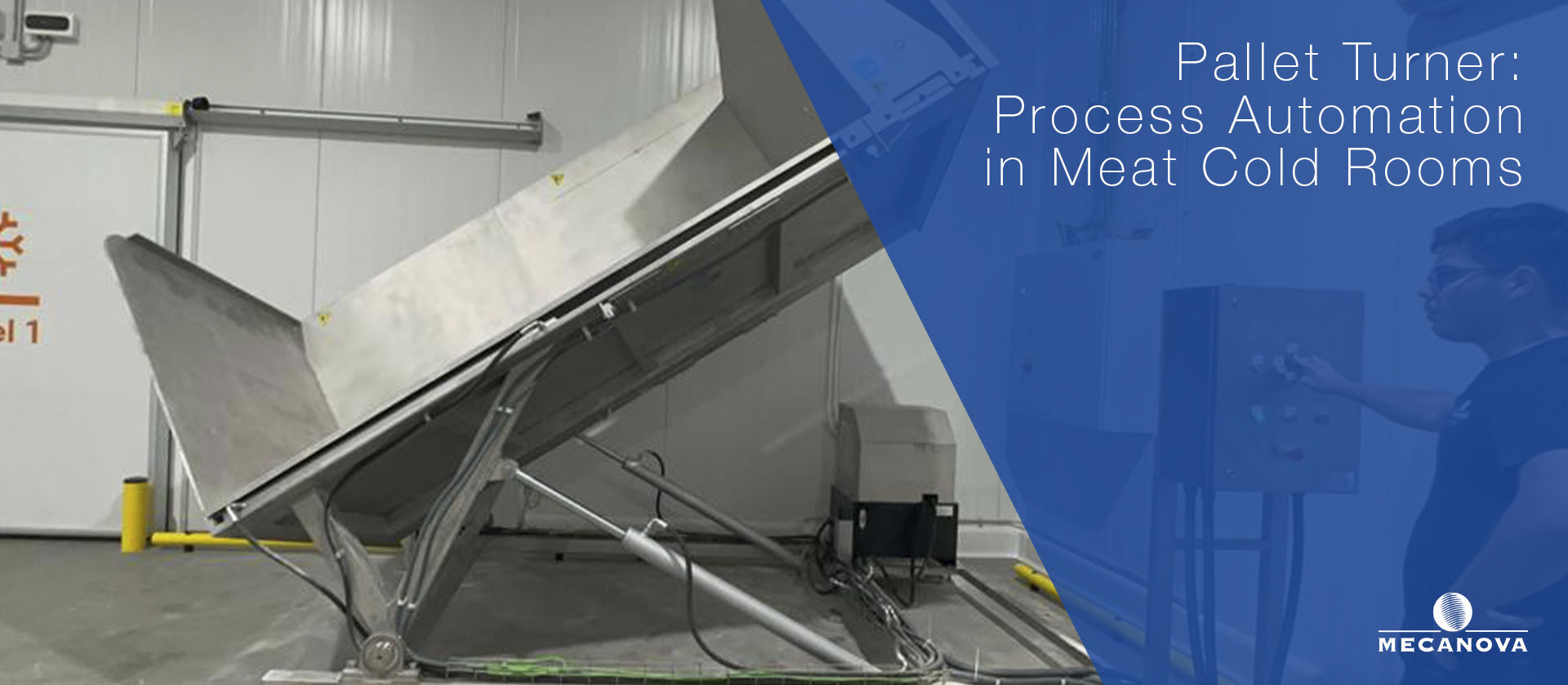

The pallet turner is a must-have piece of equipment in any frozen food export facility. The turner is a piece of equipment that facilitates the work of handling the pallets of product boxes at the exit of the freezing tunnel to remove the ventilation separators, shape and place a new pallet to ship and/or shrink wrap for storage and subsequent shipment.

Operation of the Pallet Turner

This equipment allows the placement of the pallet with boxes before or after freezing with a pallet or torito, fastened from above and below, to prevent the movement of the boxes.

First, lay down the pallet with the boxes to facilitate pallet replacement operations, insertion or extraction of dividers between levels of boxes. Then, compress and return the pallet to the upright position with all the boxes perfectly placed.

The entire operation is done without effort from the operators and free of risks to their occupational health. The equipment is made of AISI-304 stainless steel and all movements are hydraulic.

Automation eliminates the need to manually unpack and re-form pallets, reducing the handling of heavy frozen boxes. This improvement not only optimizes ergonomics and workplace safety, but also drives productivity and efficiency in the supply chain.

Pallet Turner Automation

By avoiding manual handling, automation with pallet turners improves working conditions and significantly reduces setup time. In addition, it optimizes the condition of the product, since it is not affected by manual handling, guaranteeing the quality of frozen foods. In the same way, it can also be used to remove damaged pallets and replace them with new ones or change typical wooden pallets for plastic ones.