Mecanova develops automation of blood treatment in slaughterhouses

The blood treatment automation system, a pioneer in the market, will optimise time and resources.

Mecanova keeps working on the innovation and automation of all processes in the meat industry. This time we have focused on the development of an automation system for the blood dehydration process, which we have launched in a slaughterhouse in Ukraine.

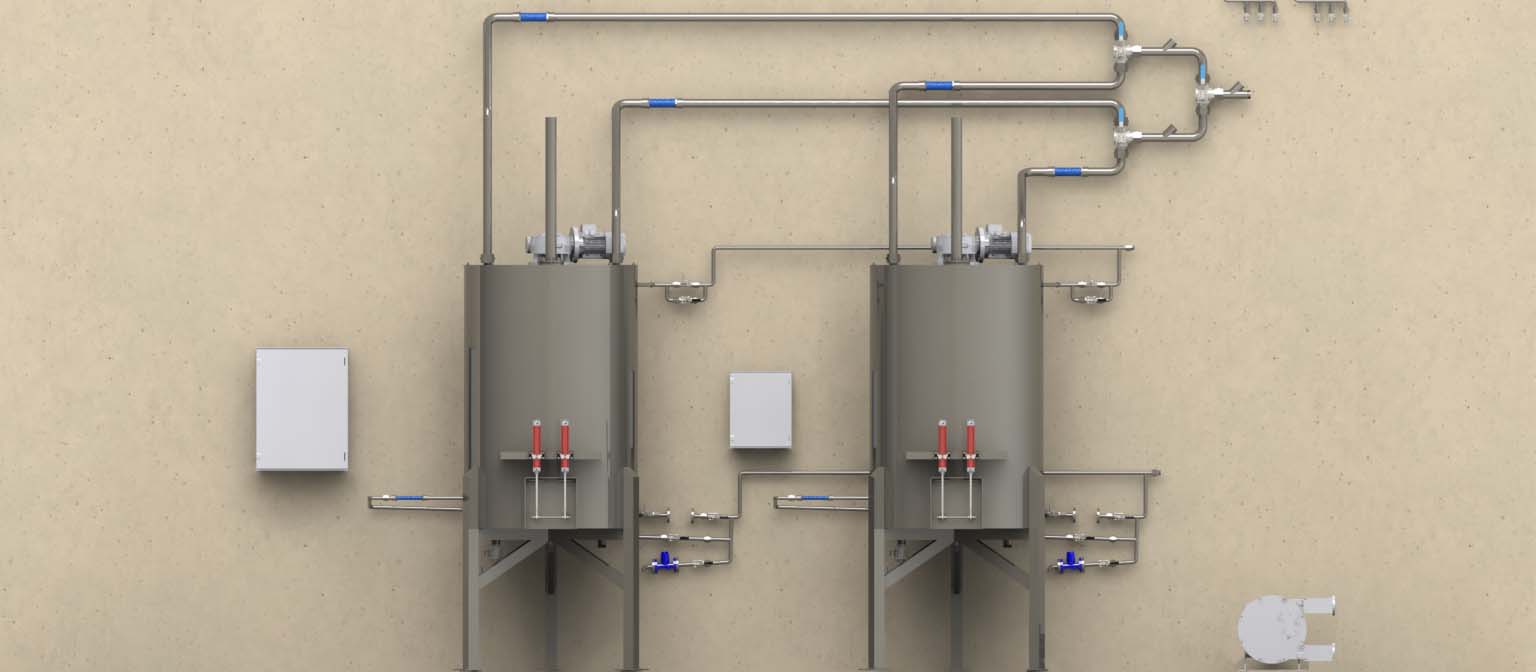

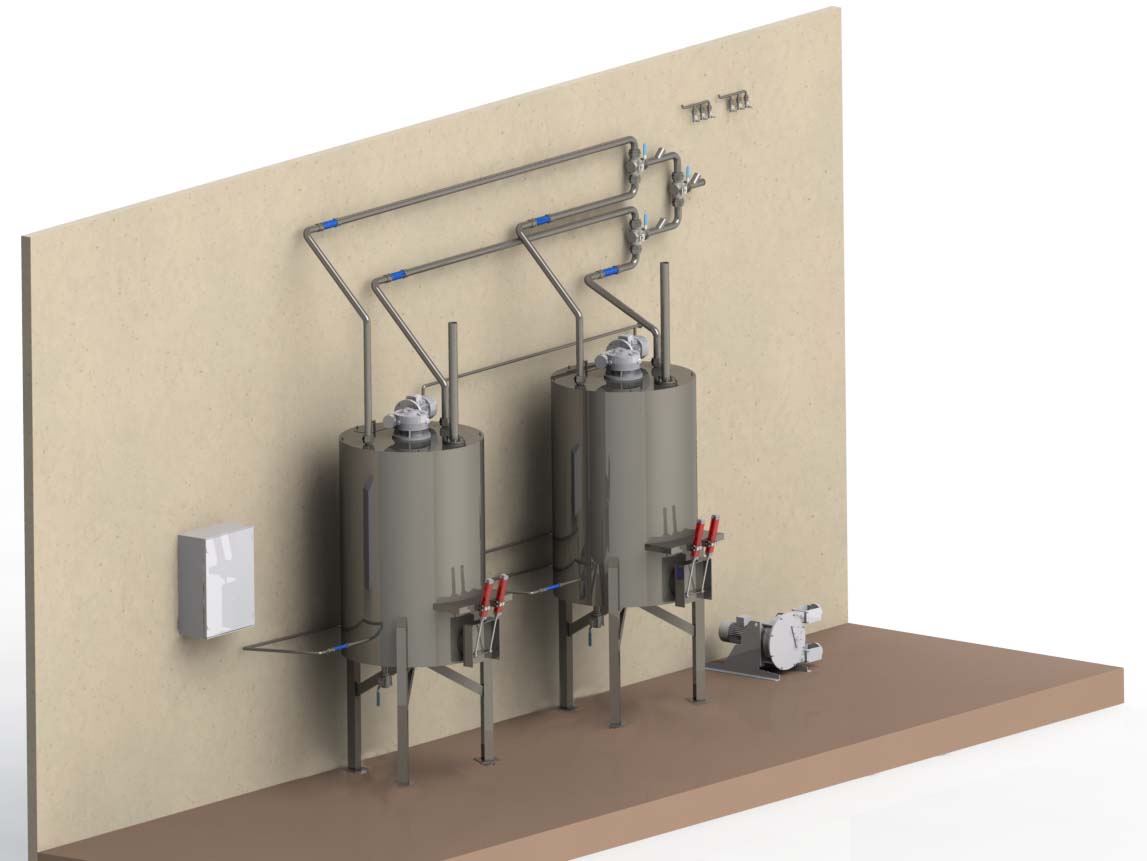

From the Ukrainian slaughterhouse facilities they wanted to solve the blood treatment issue in a more efficient and faster way. The elimination of this by-product is a problem for the water purification system. To resolve the issue, Mecanova has developed a system of blood cookers to treat blood in automatic mode, with a production capacity of 1,200 liters per hour.

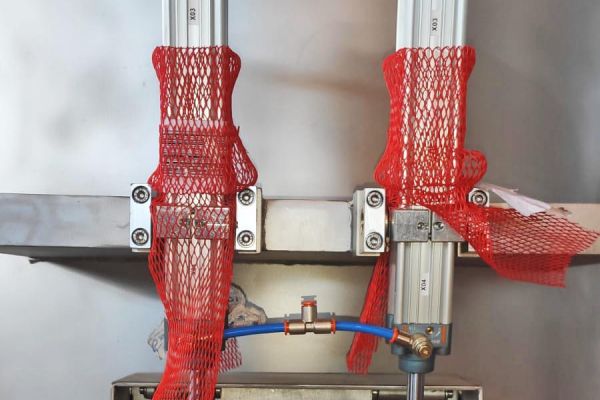

This new process consists of starting up two blodd cookers connected to the bleeding tank by means of a peristaltic pump, which alternately pumps the blood to both cookers, depending on which cooker needs to be filled at that moment. These cookers have a system that allows measuring the amount of blood that enters each one of them. When the sensors detect that the optimum capacity has been reached in the first cooker, a signal is sent to the solenoid valves to send the blood to the other cooker. While this process is taking place, the first tank is dehydrating the blood with a result of the recommended relative humidity of 40%. Once the cooking process is finished, the blood meal is expelled from cooker 1 and the process is repeated again in cooker 2. The automatic mode also includes a self-cleaning system for the entire circuit: from the pipes and valves inside the cookers. It is therefore a cyclical process that saves time and human effort, reaching a remarkable level of effectiveness in the treatment of a product that is difficult to handle.

The treatment of blood in slaughterhouses, a milestone in reducing contamination

Blood is the most polluting element in a slaughterhouse, and its treatment in the sewage treatment plant becomes quite complex and expensive that usually ends in problems. At present, modern slaughterhouses must have blood treatment systems, in order to facilitate the work of the treatment plant and save on additional costs. From defibrinators that obtain blood suitable for human consumption, to blood cookers that extract water from the blood and generate flour for use as fertilizers or animal feed.

The new blood treatment automation system represents a great step in the modernization of the facilities. In addition to completely renewing the cooking process, reducing human effort and time, the automatic mode also represents a significant advance in the ecological transition of the meat industry, by developing an optimal system that reduces pollution.